PRODUCTS

-

- Heaters & Thermo Couples

-

Heaters and temperature sensors are the crucial basic components of hot runner systems which directly impact on product quality. ERUMTECH conducts the three-stage test during the assembly process. Raw materials we use are highly resistant to oxidation, corrosion, and heat. As a result, heaters and thermocouples we make last for a long time. The temperature sensor has short response time, and few occurrences of errors from time lag. There are two types of standards of heaters and thermocouple, CA and IC.

-

Coil Heater

Working voltage of coil heater is 240V. Coil heaters made by ERUMTECH provide following properties. Excellent and stable heat. Thermal resistance. Corrosion resistance. High heat conductivity and dielectric strength.

-

Sheath Heater

Working voltage of sheath heater is 240V. This sheath heater provides enhanced dielectric strength and stability by applying terminal to the sheath. It has improved anti-shock as the insulator is covered with metallic protecting tube. The other merit of this heater is that, it can be wildly utilized in various shapes of manifold blocks.

-

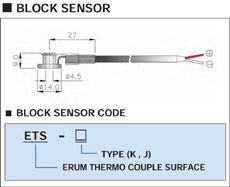

Thermo Couple for Manifold

This is a temperature sensor which is applied to manifold and is called Block sensor. This is a circular button shaped and is installed on the uppermost surface of the manifold. 2 types of standards, CA and IC are applied when it is produced. These have great resistance against heat and corrosion.

-

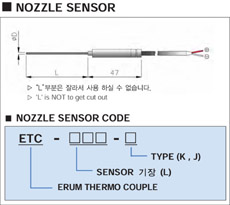

Thermo Couple for Nozzle

This is called Nozzle sensor. The tip of thermocouple is the part which installed close to the resin feeding entrance of nozzle and measures temperature. One of two standards, CA or IC is applied when it is produced. These have great resistance against heat and corrosion.

ERUMTECH

ERUMTECH